Derailleur¶

Overview¶

SRAM make a yaw-adjusting front derailleur. Generally a derailleur moves parallel to the frame, whereas a yaw-adjusting one changes pitch as it moves into position, more closely following the chain line at its extremes on the cassette.

Technically this should mean less opportunity for chain rub and make the bike easier to set up and a better, quieter riding experience. However, given the industry’s penchant to patent obvious engineering; theirs is different to the OEM Shimano system that this frame was designed for.

As the hanger is placed within a recess in the monocoque; it is not possible to simply persuade the SRAM hanger into the desired position as the derailleur will no longer fit within that recess.

Thus the 3D-printed derailleur project was born!

A bunch of iterations later; filament printed at Jaycar and fitment tested; we were ready for a production run. Interestingly, none of our prototypes proved strong enough to actually work in the field - the small amount of flex in the material induced when attempting to shift up to the big chain ring meant it was not possible to confirm with static testing.

Manufacture¶

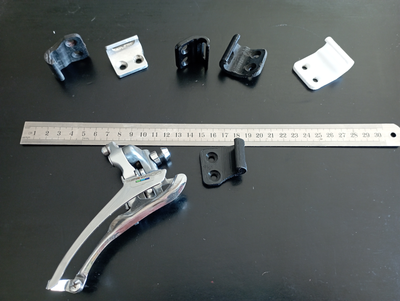

figure 1¶ |

figure 2¶ |

I was fortunate to have a tour through Sydney Manufacturing Hub and was able to get the component 3D printed in Aluminium, Selenium, Magnesium (AlSi10Mg) on a very impressive laser machine. Apparently printing components is still not without risk of failure; so two print jobs were done.

Figure 1 shows a filament version of the final design; along with the component as it came off the build plate; and then after I had cleaned and buffed it.

Figure 2 is the hanger installed, with derailleur perfectly aligned in the recess and adjusted for smooth gear changing.

We now have the worlds only SRAM-groupset Giant MCR!

STL¶

Should you too own an MCR and wish to run a SRAM groupset, I have made the solution available here.